1. Preparation Before Cleaning Check Container Integrity: Confirm that the cardboard boxes, cups, etc., are not damaged or severely deformed...

READ MORE

17oz Round Combo pack PL-18

23oz Round Combo pack PL-23

27oz Round Compo Pack PL-29

17oz Round Insert Bulk Pack PL-001

23oz Round Combo pack-Ripple PR-23

27oz Round Compo Pack-Ripple PR-29

39oz Round Compo Pack-Ripple PR-36

17oz Round Combo pack PL-718

23oz Round Combo Pack PL-723

30oz Round Combo Pack PL-729

34oz Round Container PL-737

40oz Round Combo pack PL-39

40oz Round Combo pack PL-98

50oz Round Combo Pack PL-9048

8oz Round Bowl B08

12oz Round Bowl B12

16oz Round Bowl B16

24oz Round Bowl B24

36oz Round Bowl BS36

42oz Round Bowl B42

48oz Round Bowl B48

13oz Rectangular Combo Pack PL-28

20oz Rectangular Combo Pack PL-35

23oz Rectangular Combo Pack PL-38

20oz Rectangular Combo Pack PL-7835

24oz Rectangular Combo Pack PL-7838

24oz Rectangular Combo Pack PL-6240

27oz Rectangular Combo Pack PL-68

30oz Rectangular Combo Pack PL-78

34oz Rectangular Combo Pack PL-88

27oz Rectangular Combo Pack-Ripple PR-68

30oz Rectangular Combo Pack-Ripple PR-78

34oz Rectangular Combo Pack-Ripple PR-88

27oz Rectangular Combo Pack PL-868

30oz Rectangular Combo Pack PL-878

34oz Rectangular Combo Pack PL-888

27oz Rectangular Combo Pack-High Lid PH-868

30oz Rectangular Combo Pack-High Lid PH-878

37oz Rectangular Combo Pack-High Lid PH-888

8/8oz Rectangular insert Bulk Pack PL-002

27oz Rectangular Combo Pack PL-8868

30oz Rectangular Combo Pack PL-8878

34oz Rectangular Combo Pack PL-8888

27oz Rectangular Combo Pack PL-88868

30oz Rectangular Combo Pack PL-88878

34oz Rectangular Combo Pack PL-88888

27oz Rectangular Combo Pack PL-9968

30oz Rectangular Combo Pack PL-9978

34oz Rectangular Combo Pack PL-9988

56oz Rectangular Combo Pack PL-989

40oz-PL-8140

48oz-PL-8148

54oz Roaster Container PL-1048

54oz Roaster Container PL-2048

190oz Storage Box N1

8oz Square Tamper-evident Food Container TE-08-SQ

12oz Square Tamper-evident Food Container TE-12-SQ

16oz Square Tamper-evident Food Container TE-16-SQ

24oz Square Tamper-evident Food Container TE-24-SQ

28oz Square Tamper-evident Food Container TE-28-SQ

32oz Square Tamper-evident Food Container TE-32-SQ

38oz Square Tamper-evident Food Container TE-38-SQ

42oz Square Tamper-evident Food Container TE-42-SQ

48oz Square Tamper-evident Food Container TE-48-SQ

16oz Rectangular Tamper-evident Food Container TE-16-RE

20oz Rectangular Tamper-evident Food Container TE-20-RE

24oz Rectangular Tamper-evident Food Container TE-24-RE

28oz Rectangular Tamper-evident Food Container TE-28-RE

32oz Rectangular Tamper-evident Food Container TE-32-RE

38oz Rectangular Tamper-evident Food Container TE-38-RE

42oz Rectangular Tamper-evident Food Container TE-42-RE

48oz Rectangular Tamper-evident Food Container TE-48-RE

8oz Round Tamper-evident Container R8

14oz Round Tamper-evident Container R14

16oz Round Tamper-evident Container R16

18oz Round Tamper-evident Container R18

24oz Round Tamper-evident Container R24

32oz Round Tamper-evident Container R32

8oz Tamper -Evident Combo Pack T08

12oz Tamper -Evident Combo Pack T12

16oz Tamper -Evident Combo Pack T16

24oz Tamper-Evident Combo Pack T24

24oz Tamper-Evident Combo Pack T24S

32oz Tamper-Evident Combo Pack T32

96oz Combo Pack T96

128oz Tamper -Evident Combo Pack T128

20oz Tamper-Evident Combo Pack TE-C20

32oz Tamper-Evident Combo Pack TE-C32

88oz Tamper-Evident Combo Pack TS-88

151oz barrels TS151

500oz Tamper-Evident Combo Pack TS-500

2-Compt 10/16oz Rectangular Compo Pack PL-288

2-Compt 12/15oz Rectangular Compo Pack PL-9288

2-Compt 10/16oz Rectangular Compo Pack PR-288

3-Compt 5/10/17oz Round compo Pack-Ripple PR-398

3-Compt 5/12/17oz Round Compo Pack PL-9398

3-Compt 38oz Round compo Pack-Ripple PL-598

3-Compt 8/8/10oz Rectangular Compo Pack PL-9598

3-Compt 5/5/11oz Rectangular Compo Pack PL-388

3-Compt 4/4/11oz Rectangular Compo Pack PL-9388

3-Compt 7/7/24oz Rectangular Compo Pack PL-8338

3-Compt 5/5/13oz Round Compo Pack PL-588

3-Compt 8/8/16oz Rectangular Compo Pack PL-9698

5-Compt 7/7/12/14/15oz Rectangular Compo Pack PL-9525

6-Compt 2/5/5/9/12/15oz Rectangular Compo Pack PL-9616

-

-

The barrier properties (including odor blocking) of plastic food containers depend on the density and molecular structure of the material. T...

READ MORE -

Not all plastic food containers are suitable for reuse. The key factors are the material's heat resistance, chemical stability, and ease of ...

READ MORE -

Whether you can directly heat food in a paper container in a microwave or oven is not a simple yes or no question. If you don't pay attentio...

READ MORE -

The question of whether food can be heated in paper container is a common one in everyday life. Simply put, some are safe, while others are...

READ MORE

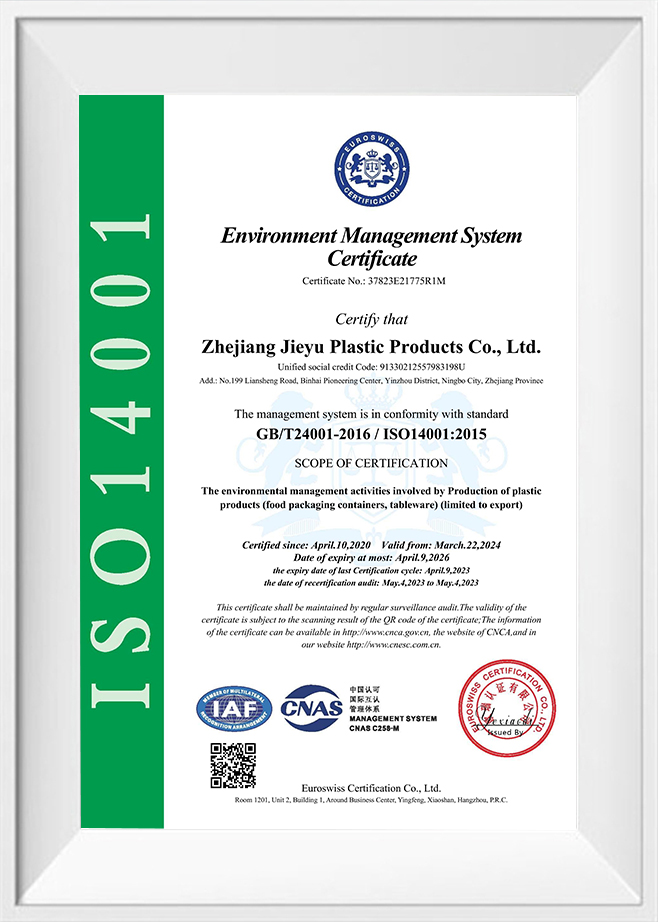

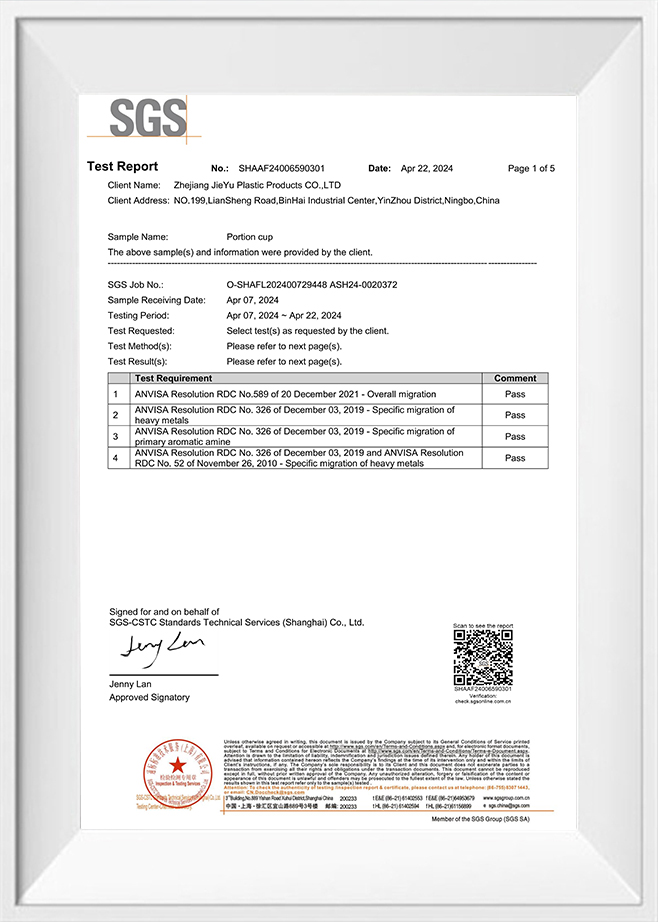

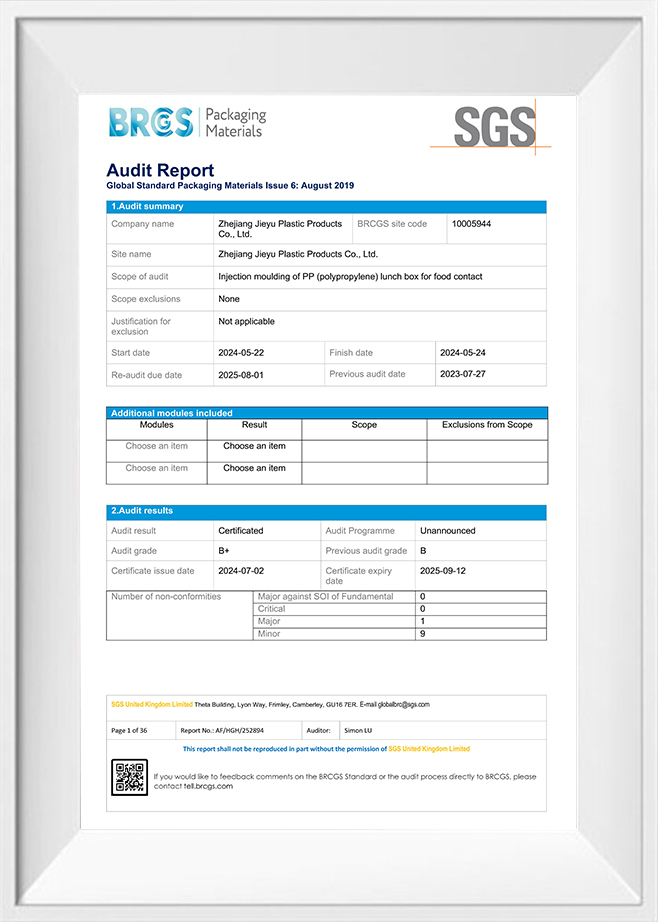

The plastic food container industry is an important part of the packaging industry and is widely used in food storage, transportation and sales. With the rapid development of the global food industry, the demand for plastic food containers continues to grow. As a company committed to sustainable development, we focus on using recyclable materials and sustainable manufacturing processes to reduce the impact on the environment. Our goal is to provide products that are not only convenient for customers to use, but also earth-friendly, ensuring that every product meets the dual standards of high quality and environmental protection.

In terms of materials, plastic food containers mainly use polyethylene terephthalate (PET), high-density polyethylene (HDPE), polypropylene (PP), polycarbonate (PC) and polystyrene (PS). PET is often used in beverage bottles and edible oil bottles because of its high transparency and good chemical resistance; HDPE is mostly used in milk bottles and detergent bottles, with strong impact resistance and chemical corrosion resistance; PP is widely used in microwave lunch boxes and yogurt cups because of its high temperature resistance and good chemical resistance; PC is often used in baby bottles and water cups for its high transparency and impact resistance; PS is mostly used in disposable lunch boxes and cup lids because of its low cost and easy processing. We always insist on using recyclable materials to ensure that products can be effectively recycled and reused after use, thereby reducing the burden on the environment.

In terms of production technology, plastic food containers are mainly manufactured by injection molding, blow molding and thermoforming. Injection molding is suitable for mass production, by injecting molten plastic into the mold and cooling it; blow molding is used to produce hollow containers, such as bottles and cans; thermoforming is to heat and soften plastic sheets and then form them through molds, which is suitable for the production of products such as trays and cup lids. In our production process, we use sustainable manufacturing processes, optimize resource utilization, reduce energy consumption and waste emissions, and strive to achieve green production.

In terms of market trends, environmentally friendly materials, lightweight, intelligent and customized are the current main development directions. With the enhancement of environmental awareness, the demand for degradable plastics and bio-based plastics continues to increase; lightweight reduces the use of plastics through material optimization and process improvement, reducing costs and environmental impact; intelligent packaging technologies, such as RFID tags and temperature sensing tags, are gradually used in food containers; at the same time, customers' demand for personalized design and customized services is also driving companies to provide more diversified products. We actively respond to market trends and continuously develop innovative products to meet customers' dual demands for environmental protection and functionality.

We are very glad that you came to JIEYU to purchase or customize, and we are confident to provide you with quality products and services.

英语

英语 中文简体

中文简体